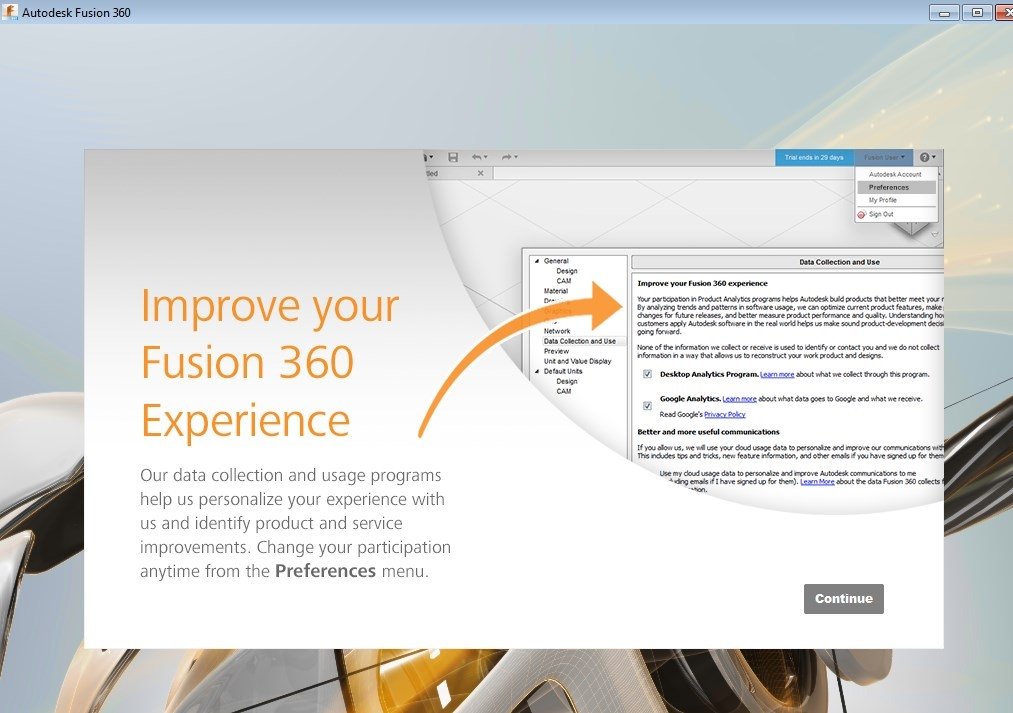

Want to engage more with the Autodesk community and test out the latest build one month before it’s released to the general public? Check out the Fusion 360 Insider program!Īnd that’s a wrap for this Fusion 360 Community Spotlight. Register for 9am PDT | 12pm EST | 5pm UK Become a Fusion 360 Insider We have 2 sessions running on Thursday, April 13th, 2023 for you to choose from, both identical in content, just at separate times. Join us for this exclusive 60-minute live event with Fusion 360 experts, where we’ll cover the latest and greatest features from all workspaces.ĭuring this webinar, we’ll also dive into improvements around flexibility, control, and programming efficiency, show off some tips & tricks and open up the floor for LIVE Q&A. How can I change my live tooling S code? Upcoming Fusion 360 Community Events Live with the Experts: What’s New in the April 2023 Release Here are some of our favorite posts from this March:

taken note of the creative solutions you’ve shared and have enjoyed watching you workshop different approaches to common problems on a daily basis throughout the forums. Yes, we’ve been lurking! We truly enjoy watching you workshop different approaches together.

We love seeing our community rally to help others on the Fusion 360 forums. See how the expert mold makers at ZETTERER leverage the Fusion 360 Machining Extension to create advanced injection and die-cast molds. To reach maximum efficiency for its Germany and Romania locations, ZETTERER recently focused on undergoing cloud-based digitalization with Fusion 360 at the center of its digital transformation. From the smallest mold you could imagine to molds that can hold 10 tons, ZETTERER is the industry expert in creating injection and die-cast molds. ZETTERER Undergoes a Digital Transformation With Fusion 360įor 55 years, ZETTERER has covered the complete spectrum of modern mold-making. PulPac expanded its digital capabilities through Autodesk’s Product Design & Manufacturing (PDMC) Collection and Fusion 360 to power further innovation and access higher-value projects. By pioneering dry fiber molding technology, PulPac’s customers can replace single-use plastics with a sustainable and cost-competitive alternative. PulPac Paves the Way for a Plastic-Free Revolution With Autodeskįounded in 2018, PulPac is on a mission to replace single-use plastics globally.

0 kommentar(er)

0 kommentar(er)